MyTechnics

The initial starting point of this project stemmed from the desire for a high quality and optically pleasing turntable. There had been tries and interest into big belt-driven massive drives -so called oil rigs- but nowadays I prefer a lean, straight appearance.

I like the design of the Bauer DPS quite alot. Conceptually it is a belt-drive with a multi-layer body. The picture shows a Naim Aro tonearm mounted.

From a technical point of view I find direct drives more elegant. The range of products of new and used turntables is still large, but the majority of new models look like copies or heirs of the Technics HiFi- and DJ-turntables. The ´big´ models are still absolute stars, but also cost correspondingly. The differences between the models are rather related to differing platter sizes and weights and the drive electronics. The platter bearing and the motors are very similar.

The 30s and 50s series from the early 80s were the first Technics featuring quartz-PLL controlled drives. With a bit of luck I could purchase a SL-5210 for 15€ on ebay. The nearly identical 10s series (SL-1210 to SL-1710) are for most far overprized. Since I was only interested in the platter and drive the condition of the frame and lid didn´t matter.

Only the condition of the platter, the bearing and motor and the electronics mattered. Fortunately the donor had been used rather less and was handled with care in a non-smoker household. The imortant parts were in mint condition.

Turntable

According to the multiple-layer concept of the Bauer DPS I designed a frame made from several layers of wooden and of dampening materials and a slate topboard.

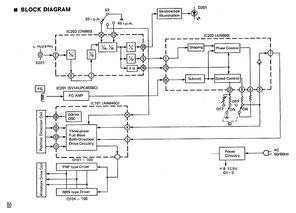

The electronic circuit builds around a set of 3 chips.

The motor-driver-IC AN640G, the PLL-control-IC AN660 and the Frequency-Generator-IC DN860.

Add to this a operational amplifier µPC4558 that conditions the signals of the frequency generator coil of the motor. At last You find a couple of transistors as motor driver-coils drivers and in the power supply regulator. Operation is accomplished with mechanical switches.

Due to the age of the subassemblies and the new design the electronics had to be serviced and updated. The mechanical switches were intended to be replaced by capacitive touch sensors.

All electrolytic caps were replaced with new and partly bigger valued types. The simple power transformer and associated rectifier was replaced by a highquality 10W switch mode power supply (SMPS).

Even though the supply voltage is regulated You can find artefacts on the PLL-voltages. This of course may degrade the sonics. The pass transistor of the voltage regulator needs to take considerably less heat power loss from the SMPSs lower output voltage and runs cooler.

The functionality was reduced to the minimum, the On/Off function and the 33/45 switchover function.

I omitted with the speed pitch and lighting, etc.

In the end the capacitive touch sensors prooved to be too sensitive in this application. So I drilled two additional small holes and changed to small mechanical push buttons. The push button pulses are translated into fixed level signals with a pair of FlipFlops.

The PCB holds two potentiometers to adjust for the exact speed and the tracking of the PLL-loop. I believe that the sound quality of a DD compared against a belt-drive is in part due to the PLL regulating loop. A DD regulates considerably faster than a belt-drive.

Within the PLL-circuitry Sample-and-Hold (S-H) circuits and Comparators are involved that´s output signals are smoothed.

That is why the Motor does not receive abrupt and stepped drive voltages/Motor-currents.

It is supplied with just enough current to keep up its speed. On occurrance of a speed deviation the motor´s drive voltage, resp. the drive current smoothly raises or falls. The often spread idea that the turntable platter receives short pushes from the motor with its full torque is deeply false.

Under daily home HiFi conditions, where a disc spins mostly undisturbed, a strong high-torque motor presents no advantage at all. A stronger motor is only capable to get the system faster into the Quartz-Lock range and to keep it there for larger, rougher deviations off of the target speed, than the weaker motor that requires more settling time and looses the lock at a lower variance. Such loads are the start-up and scratching of DJs.

A fine exemple shows in the comparison of the ´discotheque drive´ SL-1200MK2 against the ´home HiFi player´ SL-Q2. Both share the same motor and the same PLL- and motor-drive ICs.

Only the motor driver IC of the SL-1200MK2 is supplied with 21V instead of the 12V of the SL-Q2, allowing for a faster start-up time. Apart from that both players are identical in the electrically essential points.

That some DDs have a perceived slightly rough sonic diction may be well due if artefacts from the power supply can be seen on the PLL-signal, or that pulses from the Frequency-Generator-part (FG) and PLL-part may snap trough to the supply rail. Also the quality and speed of the regulation may be tuned.

Typically these are problems related to the processing and quality of the power supply.

They can be solved with the use of improved power supplies and split supply of the ICs, mainly the PLL- and the motor-driver IC. There are commercial tweaks, but those mostly exchange against a external power supply and the main voltage regulator. That isn´t consequent in fullness, but user still report of considerable improvements.

A belt-drive reacts slower because of mostly higher platter mass, lower motor torque, high speed transmission ratio, and soft coupling of motor and platter via the rubber belt. The time constants of the regulation loop, that describe how long the system needs to react and recover from an error, can be very great. In other words runs a belt drive hardly ever at the precise speed, resp. it runs with greater speed variation than a DD. Well designed and adjusted a DD is at least at eye level with a belt drive.

Tonearm

As tonearm for this project a Rega RB300 comes to use,which I bought several years ago but have never put on a deck. The Rega´s optics and capabilities are well known. On the plus-side we find a cast arm tube, robust bearings, spring adjusted tracking force and loads of info on the internet. On the minus-side we see minor flexibility due to missing height- and azimuth adjustement, a fixed headshell, rather low quality bearings and partly great tolerances in finish quality. Its straight optical appearance fascinates today still the same as it did new into the market in the 80s. It fits well to the reduced design of the MyTechnics.

The arm underwent three modifications. First I changed the cabling, second the tracking force spring got some form of damping and third had I have turned a heavier counterweight. The modifications are easy to perform without having to dismantle the complete assembly. Interestands find manuals on the internet.

For the counterweight I did some calculations and made a drawing, so that it fits my ca. 12gr weighing pickup.

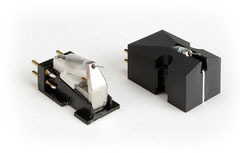

Pickup

The pickup is a MusicalLife Andante. Its based on a Denon DL-103. It comes with a new cantilever with a Shibata needle, a heavier wooden casing and cryogenic treatment. All together it leads to a higher resolution of fine details without loosing on the strengths of the Denon like the nice and lively midrange.

Die Nutzung der Texte, Bilder und Informationen auf dieser Webseite in Teil oder in Gänze bedarf meiner Zustimmung. The useage of the texts, pictures and information contained on this website in parts or in fullness requires my admittance.

Diese Webseite wurde mit Jimdo erstellt! Jetzt kostenlos registrieren auf https://de.jimdo.com